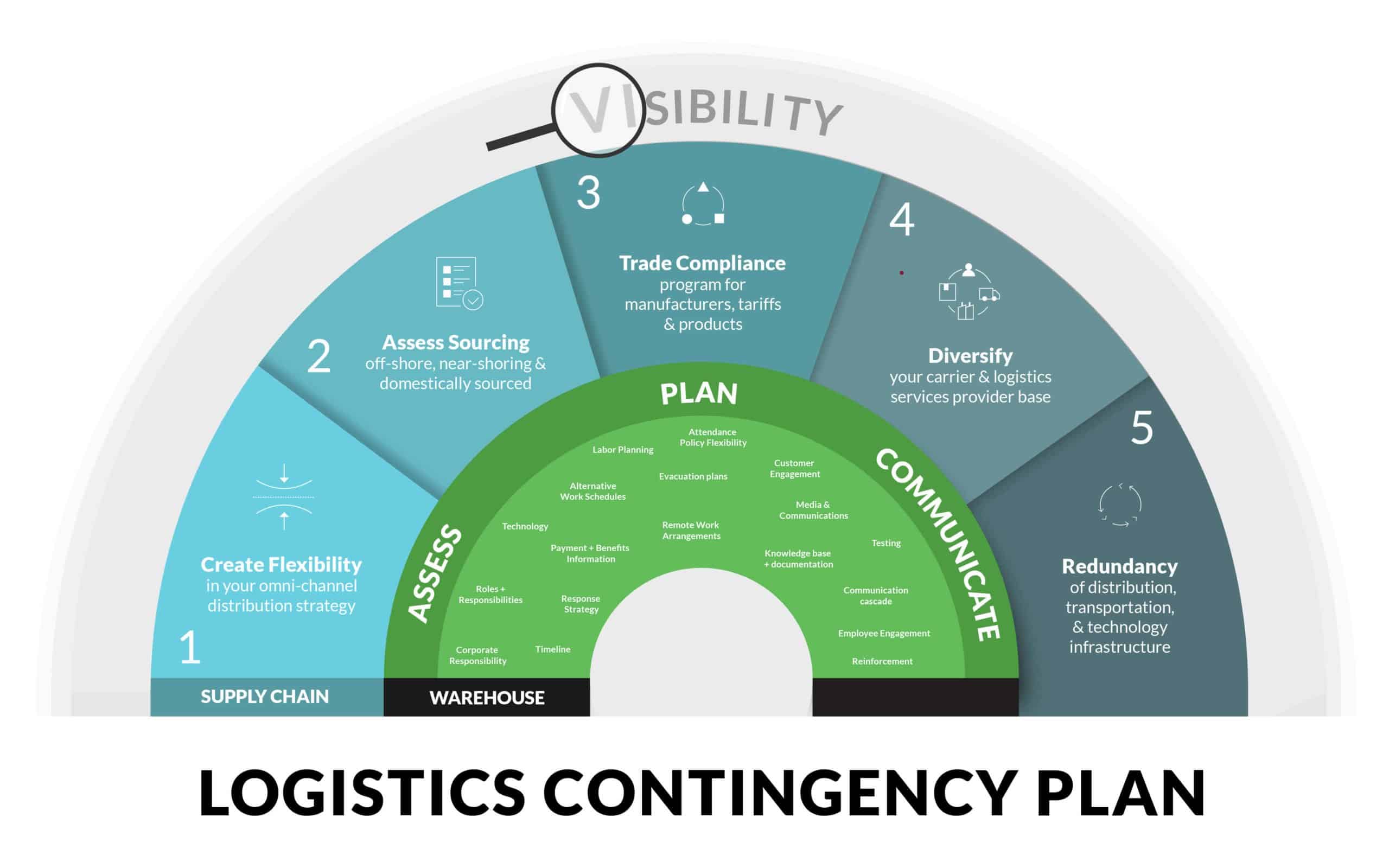

Aligning Your Supply Chain and Warehouse Contingency Plans [INFOGRAPHIC]

Even the slightest change in the global supply chain can have a major ripple effect. To that end, it’s vital that organizations develop comprehensive logistics contingency plans, both at the supply chain and warehouse levels, in order to mitigate or prevent the negative effects of supply chain disruption.

As you can see in the image below, we’ve outlined the components of both a supply chain and a warehouse logistics contingency plan. Although each plan is unique, they both follow the same basic process — assess, plan and communicate — and require a high degree of visibility. For a more detailed explanation of why contingency planning is so essential, and how to develop a logistics contingency plan, please refer to our blog posts on the subject:

- COVID-19 Crisis Sheds New Light on Need for Logistics Contingency Plan

- Assess, Plan & Communicate: The 3 Steps to Creating a Warehouse Contingency Plan

Get Insights. Stay Ahead.

Get the latest news and insights via email on warehouse improvement, transportation optimization, labor strikes and international shipping rate changes.Popular Posts

Search Posts

-

Global Momentum Builds for Charge on Global Shipping Sector’s CO2 Emissions

A growing coalition of 47 countries, including key players like the European Union, Canada, Japan, and various Pacific Island nations, is...

+ Read more -

5 Key Components in International Contingency Planning

The global logistics outlook indicates a lingering crisis mode, requiring adaptation to the new normal of accelerated global disruptions,...

+ Read more -

Mexico Surpasses China as Top US Trade Partner in 2023

Mexico Surpasses China as Top US Trade Partner New data released earlier this month by the Commerce Department shows that Mexico has...

+ Read more