Assess, Plan & Communicate: The 3 Steps to Creating a Warehouse Contingency Plan

Warehouse contingency plans: You hope you’ll never need them; but without one, you’re stuck.

In early 2020, suddenly warehouses everywhere were forced to pivot in order to cope with stay-at-home mandates, labor shortages and massive surges in demand due to COVID-19. Among many other things, this experience laid bare the supply chain-wide need for comprehensive contingency plans for emergencies of all kinds.

In this blog post, we’ll outline the three key steps to creating a foolproof warehouse contingency plan, so your business’ supply chain does not get disrupted.

Download Our Logistics Contingency Plan Template >

Warehouse Contingency Plan Risk Management

Before we get to the three-step process of building a contingency plan, let’s define its role in risk mitigation and management.

In the modern supply chain, warehouses serve as pivotal nodes, facilitating the smooth flow of goods from manufacturers to consumers. However, with this central role comes inherent risks, ranging from natural disasters to supply chain disruptions and operational failures. This is one reason why robust warehouse contingency plans should serve as a cornerstone of an effective risk management strategy.

At its core, warehouse contingency planning is a proactive approach to identifying, assessing and mitigating risks that could jeopardize the continuity of warehouse operations. It involves a comprehensive assessment of potential threats and vulnerabilities, followed by the development of strategies and protocols to address these challenges swiftly and effectively.

One of the primary objectives of warehouse contingency plans is to enhance operational resilience — the ability to adapt and respond swiftly to unforeseen events while maintaining core functions and service levels. Warehouse owners and managers can achieve this by investing in proactive risk management strategies, including:

- Diversifying suppliers

- Optimizing inventory management practices

- Implementing redundant systems

- Fostering open communication channels and establishing mutual support agreements with partners and suppliers

- Synchronizing contingency measures with appropriate stakeholders

Warehouse contingency plans also play a crucial role in safeguarding against financial losses. The costs associated with downtime, inventory spoilage and reputational damage can be significant — further illustrating the critical importance of warehouse contingency planning in proactive risk management.

Warehouse Contingency Plan Course of Action

Step One: Assess Warehouse Contingencies

The first step to creating an effective contingency plan is to perform a risk assessment within your warehouse.

- Start by mapping out business-critical processes, procedures, technologies and personnel to create a foundation for your warehouse contingency plan. At the risk of stating the obvious, these operations are the cornerstone of your business, and must carry on normally even in the event of an emergency.

- Next, imagine various worst-case scenarios and formulate a response for each. For example, how would your process for receiving shipments need to change in the event of a natural disaster? Regulatory compliance issues? A pandemic

In addition to providing a foundation for your warehouse contingency plan, this assessment should also help you identify opportunities to reduce or eliminate risk before it even happens. For example, strictly enforced workplace sanitation and rigorous protective measures can prevent employees who work with hazardous materials from getting sick on the job.

Step Two: Determine Warehouse Contingency Plan

Once you’ve completed your risk assessment, you’re ready to create your warehouse contingency plan. Whether it’s in response to a global event or something as simple as an equipment malfunction, every warehouse contingency plan should outline:

- Specific triggers. These dictate what will set your plan in motion. For example, if you have a hurricane contingency plan, at what point does it go into effect — during a hurricane warning or a hurricane watch?

- Response strategy. Your plan should include a brief overview of how your warehouse staff should respond to the situation at hand.

- Key roles and responsibilities. Clearly define who is responsible for enacting different parts of the plan and what is expected of them. Be as specific as possible to prevent any confusion. This section of your contingency plan should clearly assign backups to all key positions and ensure that proper training has been conducted with all parties.

- Leadership depth and training. In addition to outlining responsibilities for executing your contingency plan, it’s also important to prepare the site so that it’s operational even when key leaders are not able to be present. Align primary and secondary fallback resources for mission-critical responsibilities and train your workforce accordingly. Continuous training and cross-training efforts within the warehouse will prove an invaluable time investment should disaster strike.

- Technology. One of the most critical elements of any warehouse contingency plan is a thorough schematic of all technology systems. Today, most of our data lives in the cloud, as do many business applications. To that end, it’s important that you establish proper redundancy — in both your cloud-based storage and data centers — in the event that that data should become unavailable. There are many systems and connection points involved in creating transactions within a supply chain and providing visibility upstream and downstream from the distribution center. Your plan should address each of the systems you rely on — such as warehouse management systems, warehouse control systems, labor management and timekeeping systems, enterprise resource planning systems and transportation management systems — as well as any of the systems they connect to.

- Labor. Another critical element of a warehouse contingency plan is to have labor providers and staffing agencies in your back pocket. Take care to fully vet each vendor’s ability to provide qualified workers who won’t be disruptive to your team’s culture.

- Timeline. Explain to your employees when each step of your contingency plan should take place — for example, whether an action needs to occur within the first hour of the plan being implemented or the first day.

- Alternative work schedules. Certain emergency scenarios will require you to drastically reduce the number of onsite employees. Build alternative work schedules into your warehouse contingency plan to ensure that all of your business-critical operations are completed, even with a reduced workforce.

- Remote work arrangements. If there’s anything the early 2020s taught us, it’s that every business — even warehousing — needs to have a plan in place for remote work arrangements. Your warehouse contingency plan should detail which workers are considered essential and which ones can work from home; be sure to provide the necessary resources and equipment to help remote workers get set up.

- Attendance requirements. Depending on the nature of the emergency, employees may be unable to attend work due to mitigating circumstances, such as a lack of child care, health issues or family obligations. Employees who find themselves in this position may be reasonably concerned that their absence will affect their workplace performance. When creating your warehouse contingency plan, be sure to include information about attendance requirements and expectations and policies to address these concerns.

- Payment and benefits information. Similar to attendance, depending on the nature of the emergency, your employees may have concerns about payment and benefits. Take care to include specific information about both in your warehouse contingency plan.

- Corporate responsibility. For more high-risk scenarios, it’s important that you demonstrate to your staff that your organization is taking the necessary precautions to ensure their safety. Provide detailed explanations of workplace safety protocol, as well as offer a point of contact who can field employee questions or concerns.

- Evacuation plans. In some situations — say, a flood or a fire — it may be necessary to evacuate your staff from the warehouse. To accommodate for this possibility, your contingency plan should include specific instructions on how to proceed, as well as clearly outline an evacuation route.

- Communication models. It’s important that your contingency plan map out a structured flow of communication, and that you have prepared message templates readily available. This is imperative not only for internal communications, but also for potential external communication should the situation garner media attention. We’ll go into this further in the next section.

Warehouse Contingency Plan Examples

The following two examples illustrate the importance of having comprehensive contingency plans in place to address various types of risks and ensure operational resiliency. The first provides a general plan for an immediate threat, while the second addresses a more proactive approach to a much larger industry disruption.

Natural Disaster Contingency Plan:

- Identify potential natural disasters that could affect the warehouse, such as hurricanes, earthquakes or floods.

- Develop building evacuation procedures in case of imminent danger.

- Implement storage strategies to minimize damage to goods, such as elevating inventory or using waterproof containers.

- Establish communication protocols for informing employees, suppliers and customers about the situation and any disruptions to operations.

- Have backup power sources in place, such as generators, to ensure essential systems remain operational during power outages.

- Establish relationships with alternative suppliers and logistics partners to mitigate disruptions in the supply chain.

Supply Chain Disruption Contingency Plan:

- Identify potential risks to the supply chain, such as supplier failure, transportation disruptions or geopolitical events.

- Diversify the supplier base to reduce dependence on a single source for critical materials or components.

- Maintain safety stock levels to buffer against short-term disruptions in the supply chain.

- Develop alternative transportation routes and logistics partners to mitigate disruptions in case of road closures, port strikes or other transportation-related issues.

- Establish clear communication channels with suppliers and customers to provide updates on any disruptions and coordinate alternative solutions.

- Regularly review and update the contingency plan based on changes in the supply chain landscape or lessons learned from previous disruptions.

Step Three: Communicate Your Warehouse Contingency Plan

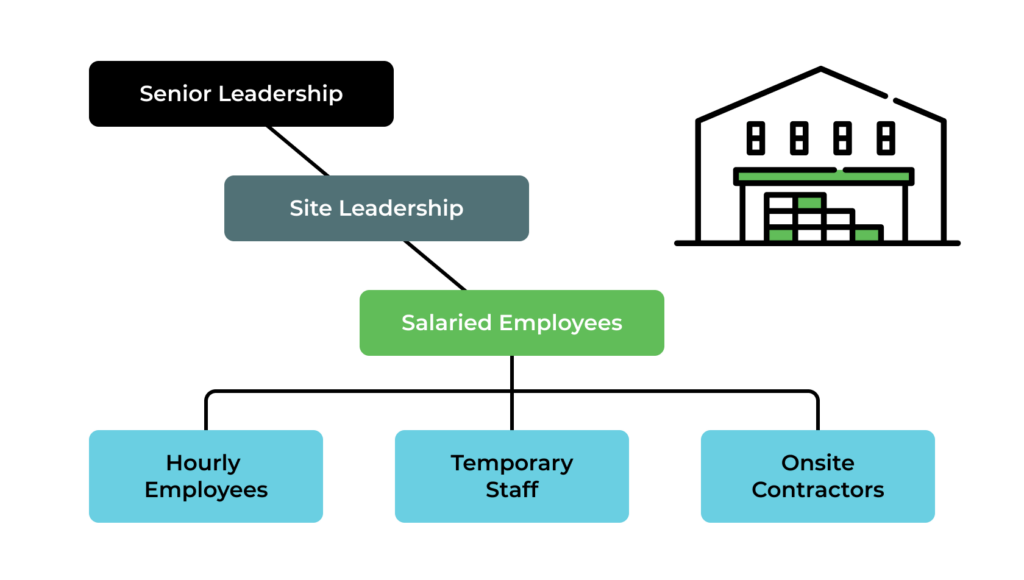

Once you have a fully formed warehouse contingency plan, it’s time to implement it across all levels of your business — and in order to do that, you must first clearly communicate it to all levels of your business. After all, it hardly seems reasonable to expect your warehouse staff to respond appropriately in the event of an emergency if your senior leadership team never provided specific instructions for how to do so.

The best way to do this is to start by determining the different groups within your warehouse. For example, your site leadership team might consist of a facility manager, an HR manager, an operations manager, and various supervisors. This group should be separate from your senior leadership team, which might consist of VPs and C-suite executives. You might also consider bucketing your warehouse staff into separate groups based on whether they’re salaried, hourly, or temp workers or, alternatively, based on roles like receiving dock, inventory control, and shipping.

The next step is to create a tiered chain of communication so that individuals in leadership positions have a clear understanding of whom they’re responsible for delivering information to. A typical warehouse organizational structure will look something like the following:

Now that you have the “what” and the “who” of your warehouse contingency plan, the next step is to figure out the “how” and the “when.”

Let’s start with the “how.” There are any number of ways to communicate your contingency plan to your warehouse staff. However, with so many moving pieces in a warehouse environment, it’s important to think through a few cornerstone elements.

Knowledge Base and Documentation: Your knowledge base should consist of documentation that your employees can refer to for guidance on how to respond to different disaster scenarios. For example, a pandemic response plan should include:

- Sanitation guidelines

- Social distancing requirements

- Travel and work-from-home guidelines

- Protective standard operation procedures, including temperature screenings and protective face coverings

- Attendance and time off policy adjustments

- Exposure case definitions and contact tracing procedures

- Employee “safe passage” documentation and essential business definition (with guidance on applicable local, county, state and federal legislation)

- Protocol for handling an infected associate in the workforce

- Protocol for handling onsite vendors and visitors

- Related human resources policies, forms and documentation

Your warehouse contingency plan knowledge base should include documents with specific instructions for each of the topics listed. It’s also recommended that you create an employee FAQ that your staff can refer to if they have additional questions about your contingency plan. An important note: These should be considered living documents and should be regularly updated with new information to ensure accuracy.

Communications Cascade: An effective communications cascading process will reach all groups across multiple channels. Meetings — be they stand-up meetings, work group meetings, or town halls — are another effective way to communicate your warehouse contingency plan to your staff. This method of delivering information is not only more immediate, it also gives employees the opportunity to ask questions and gain a better understanding of how to proceed. We also recommend that you incorporate visual communication wherever possible, since studies show that 67% of employees are better at completing tasks when information is communicated by video or by text with images rather than plain text alone.Ideally, your warehouse contingency plan communication effort should be multi-faceted so that messaging is consistently reinforced.

Reinforcement: With the “how” out of the way, the “when” is fairly straightforward: You should communicate your organization’s contingency plan to warehouse staff well in advance of an actual emergency. There’s really no way to accurately predict when disaster might strike, so it’s important that your employees be prepared no matter what. Communicate with your employees early and often, whether that’s once a month, once a week, or even every day — however long it takes for the information to really sink in.

Engagement: Most communication efforts are minimally effective if there’s no two-way dialogue. It’s important that you create a feedback channel and use the resulting information to develop active next steps. Surveys, quizzes, train-the-trainer events, role playing, suggestion boxes, contests… There are countless ways to establish a two-way dialogue to reinforce the understanding of and get your employees to engage with your contingency plan.

Testing: Contingency planning and business continuity are all about preparation and diligence. Although it might seem like overkill, creating mock scenarios in which key staff are required to activate certain elements of your contingency plan can prove invaluable should you ever have to actually enact it. From practicing technology fail-overs to being able to pick and process orders manually to moving large groups of people to a safe area, there are any number of ways to practice your warehouse contingency plan ahead of time in a controlled environment.

Download Our Logistics Contingency Plan Template >

—

When times get tough for your supply chain, Legacy SCS is here to help. Don’t hesitate to contact us with any questions you might have about warehouse contingency planning, or if you’d like to learn about any of our third-party logistics services or solutions.

Get Insights. Stay Ahead.

Get the latest news and insights via email on warehouse improvement, transportation optimization, labor strikes and international shipping rate changes.Popular Posts

Search Posts

-

2024 Q1 Freight Landscape: Trends, Challenges, and Predictions

As the first quarter of 2024 comes to an end, here are some observations over the past few months as well as predictions about the trucking...

+ Read more -

Baltimore Bridge Impact Assessment – Update

Following the recent Baltimore Bridge collapse and subsequent port closures, we want to keep our customers informed about the situation and...

+ Read more -

Global Momentum Builds for Charge on Global Shipping Sector’s CO2 Emissions

A growing coalition of 47 countries, including key players like the European Union, Canada, Japan, and various Pacific Island nations, is...

+ Read more