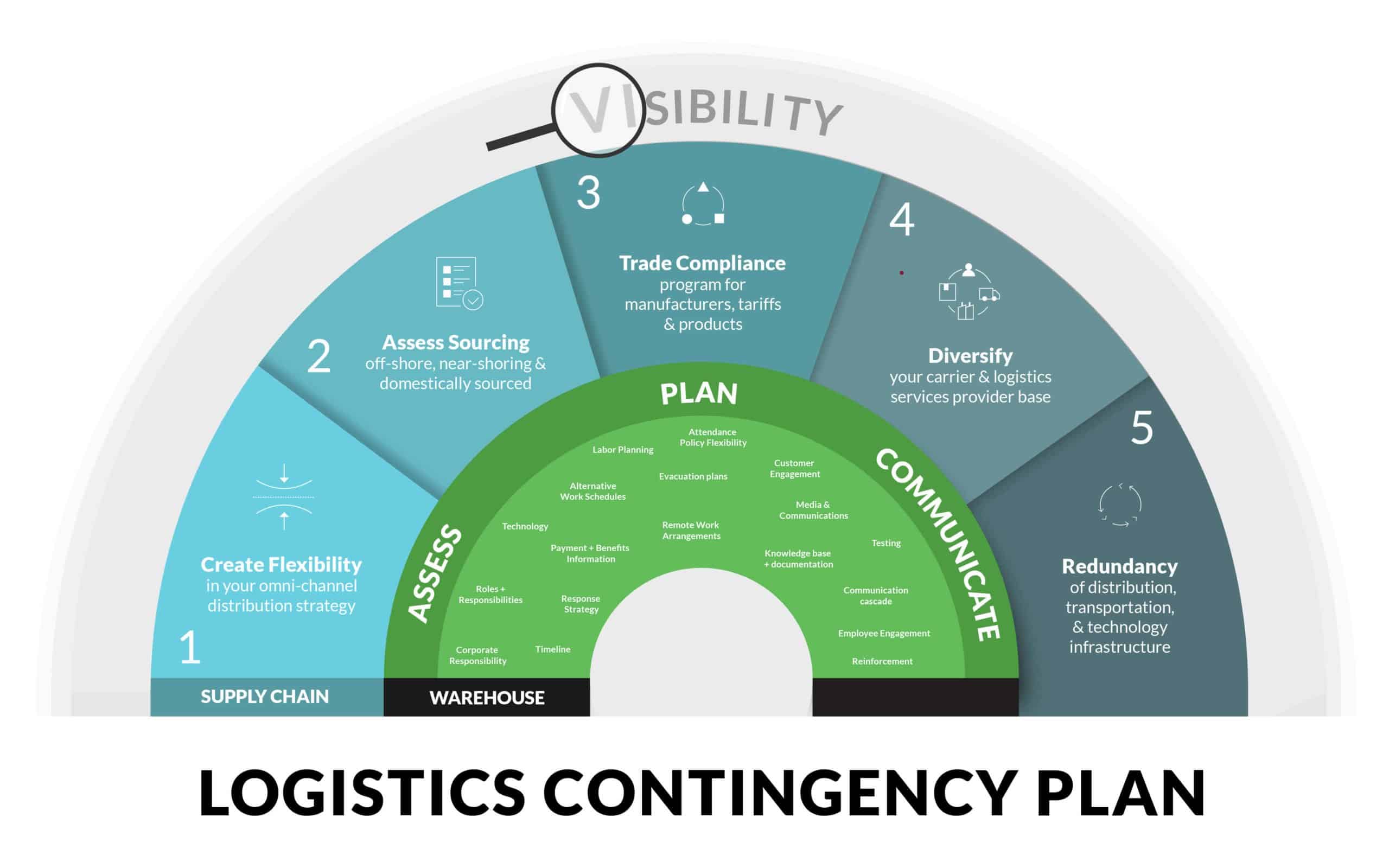

Aligning Your Supply Chain and Warehouse Contingency Plans [INFOGRAPHIC]

Even the slightest change in the global supply chain can have a major ripple effect. To that end, it’s vital that organizations develop comprehensive logistics contingency plans, both at the supply chain and warehouse levels, in order to mitigate or prevent the negative effects of supply chain disruption.

As you can see in the image below, we’ve outlined the components of both a supply chain and a warehouse logistics contingency plan. Although each plan is unique, they both follow the same basic process — assess, plan and communicate — and require a high degree of visibility. For a more detailed explanation of why contingency planning is so essential, and how to develop a logistics contingency plan, please refer to our blog posts on the subject:

- COVID-19 Crisis Sheds New Light on Need for Logistics Contingency Plan

- Assess, Plan & Communicate: The 3 Steps to Creating a Warehouse Contingency Plan

-

Legacy Achieves Platinum Status for Delivery Excellence From Amazon

When it comes to supply chain performance, the margin for error is razor thin. Customers expect orders to arrive quickly, accurately, and...

+ Read more -

IPS Corporation selects Legacy as 3PL Partner to drive Supply Chain Transformation

FRANKLIN, IN | September 10th, 2025 – Legacy SCS announced that it has been selected by IPS Corporation, a global leader in Water...

+ Read more -

How GForce Transformed Its Supply Chain Into a Powerful Growth Engine

When GForce Arms launched in 2020, the mission was simple but ambitious: deliver affordable, reliable firearms with the speed and...

+ Read more