Small Parcel Processing Company

Customer Success Story: Sporting Goods

Business Issue: Warehouse Inefficiencies, Delayed Order Processing

Company Overview

This case study outlines LEGACY’s work with a leading sporting goods company. They have sold over 100 million units of their core product. In recent years, they have expanded their offerings considerably, offering many complimentary products within their field. Nearly 2 million units are manufactured each year, with an average of 3,000 units made each day at their main facility. During peak production time, the factory increases production to approximately 5,000 units per day.

The Challenge:

West coast distribution operation unable to meet demand in small parcel processing area during peak season. Warehouse inefficiencies manifested challenges such as:

- Processing orders 5 days behind schedule – double space utilization

- Multiple areas of high demand made it difficult for staff to maintain the flexibility necessary to process overdue orders

- High degree of experience required in two key processing areas

The client needed an immediate solution to restore small parcel processing to current processing.

The Solution:

LEGACY came in with an immediate response: a two-day focused support of lean platform leaders with a Lean Action Workout (AWO). During this Lean AWO, LEGACY:

- Observed packing and shipping processes

- Stress-tested process output variability, process capability, and cycle times

- Separated work elements by task complexity

- Compartmentalized most complex tasks to skilled workers

- Created “waterspider” role to handle multiple tasks, allowing skilled workers to keep processing

- Identified 19 additional opportunities that should be addressed with future Lean AWO

Value and Results:

As a result of the Lean AWO, there was an 85.74% improved maximum capacity rate of small parcel processing at peak production.

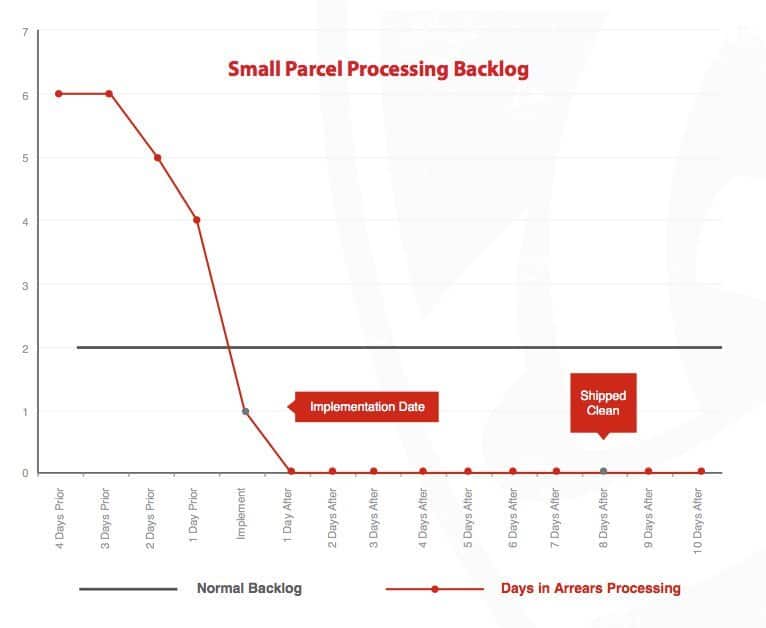

- Turnaround time was moved from 5 days behind schedule in small parcel processing to processing current deliveries within 48 hours of implementation.

- Staging area was decreased to two lanes: current day work and booking orders.

- Maintained processing current-day work for 12 consecutive data points

In addition to these improvements, the workout session also identified significant opportunities for future improvements in footprint utilization and overprocessing.

“We were proud to help our client improve shipment processing by over 80% during peak season and exceed service expectation goals.”

–LEGACY Lean and Quality Team

Get Insights. Stay Ahead.

Get the latest news and insights via email on warehouse improvement, transportation optimization, labor strikes and international shipping rate changes.Popular Posts

Search Posts

-

2024 Q1 Freight Landscape: Trends, Challenges, and Predictions

As the first quarter of 2024 comes to an end, here are some observations over the past few months as well as predictions about the trucking...

+ Read more -

Baltimore Bridge Impact Assessment – Update

Following the recent Baltimore Bridge collapse and subsequent port closures, we want to keep our customers informed about the situation and...

+ Read more -

Global Momentum Builds for Charge on Global Shipping Sector’s CO2 Emissions

A growing coalition of 47 countries, including key players like the European Union, Canada, Japan, and various Pacific Island nations, is...

+ Read more