The Complete Logistics RFP Playbook: How to Secure the Right 3PL for Your Business

Choosing a third-party logistics (3PL) provider isn’t just another procurement exercise — it’s a critical strategic decision that will impact your supply chain’s efficiency, cost structure and your ability to meet customer expectations. While the right 3PL partner can help you drive long-term operational improvements, from reducing transit times and optimizing inventory levels to increasing network flexibility and mitigating risk, the wrong one can do just the opposite. Think persistent inefficiencies, service failures and unexpected costs that ripple across your entire operation.

That’s why the request for proposal (RFP) process matters — not just the document itself, but every step leading up to and following it. Too often, companies send out vague, boilerplate logistics RFPs that fail to attract the right providers or, worse, don’t receive any responses at all. A well-executed RFP process is about more than just finding a 3PL — it’s about getting 3PL providers capable of meeting your needs, both now and in the future, to engage with you in the first place.

In this guide, we’ll break down every single stage of the logistics RFP process, from defining your needs to evaluating proposals, so you can secure a partner that delivers meaningful results.

Want to get a jump start on your logistics RFP? Download our free template to get started.

What Is an RFP?

A request for proposal is a formal document companies use to solicit bids from potential service providers. In logistics, an RFP enables businesses to evaluate prospective 3PL providers based on their capabilities, pricing and overall fit. Unlike an informal inquiry or exploratory conversation, a logistics RFP provides a structured framework for comparing providers, ensuring that respondents address the same set of criteria in a way that allows for meaningful evaluation.

A well-written RFP is more than just a tool for collecting bids — it’s a strategic document that enables a company to find a logistics partner capable of meeting its immediate operational needs and cost objectives, as well as its long-term growth plans. As such, it should outline specific business requirements, expectations and evaluating criteria, giving prospective 3PL partners everything they need to develop accurate, tailored proposals.

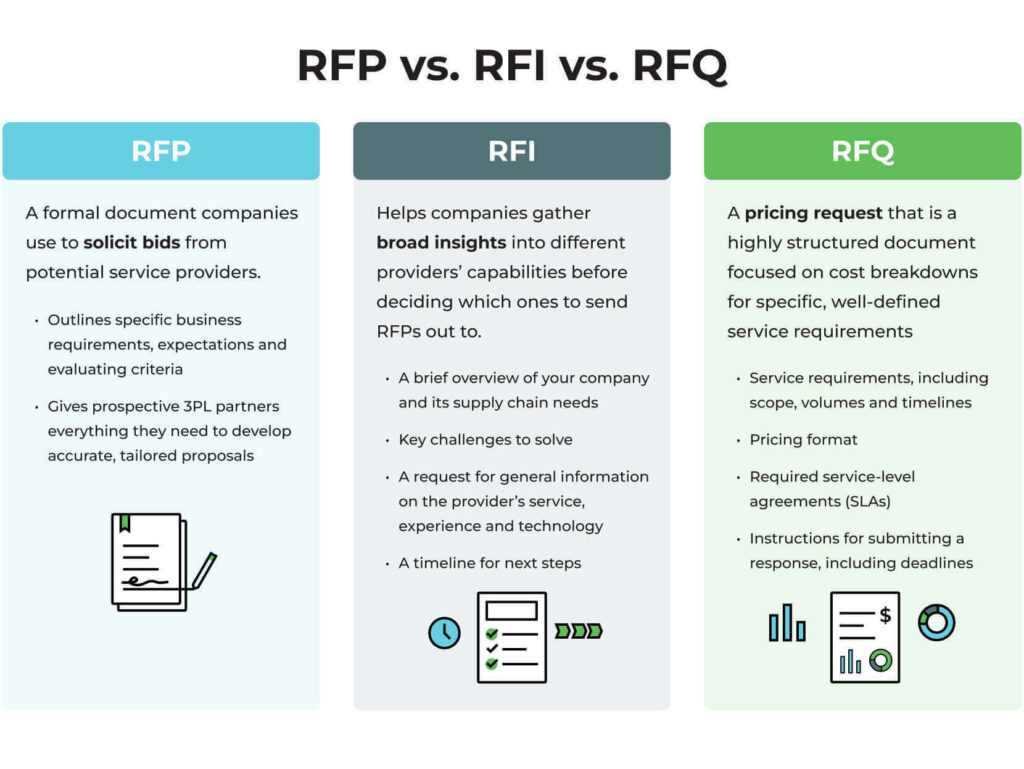

RFP vs. RFI vs. RFQ

If you’re planning for or actively undergoing a logistic RFP process, you might’ve heard the terms “request for information” and “request for quote.” These are two documents that, while closely related to RFPs, serve distinct roles within the 3PL selection process.

Used early in the selection process, a request for information (RFI) helps companies gather broad insights into different providers’ capabilities before deciding which ones to send RFPs out to. RFIs are particularly useful if your company is considering outsourcing for the first time or evaluating providers you haven’t worked with before. They should include:

- A brief overview of your company and its supply chain needs

- Key challenges you’re looking to solve

- A request for general information on the provider’s service, experience and technology

- A timeline for next steps, including when you might issue an RFP

If you’re considering sending out a logistics RFP but aren’t sure which 3PLs to include, you may want to start with an RFI to gather general information.

A request for quote (RFQ) is a pricing request sent to providers that have already been vetted. It’s a highly structured document focused on cost breakdowns for specific, well-defined service requirements. Companies typically issue RFQs when they have a clear understanding of their needs and are primarily focused on pricing comparisons. An RFQ should include:

- Detailed service requirements, including scope, volumes and timelines

- Pricing format (e.g. per unit, per pallet, per shipment)

- Required service-level agreements (SLAs)

- Instructions for submitting a response, including deadlines

If you have a shortlist of 3PL candidates and just need pricing, an RFQ may be sufficient.

While most companies issue RFIs or RFQs before sending out RFPs, some prefer to include RFI- or RFQ-style sections within their logistics RFP to capture both qualitative insights and structured pricing details in a single document. Doing so helps ensure providers submit comprehensive, comparable responses, making it easier to identify the best fit for your business.

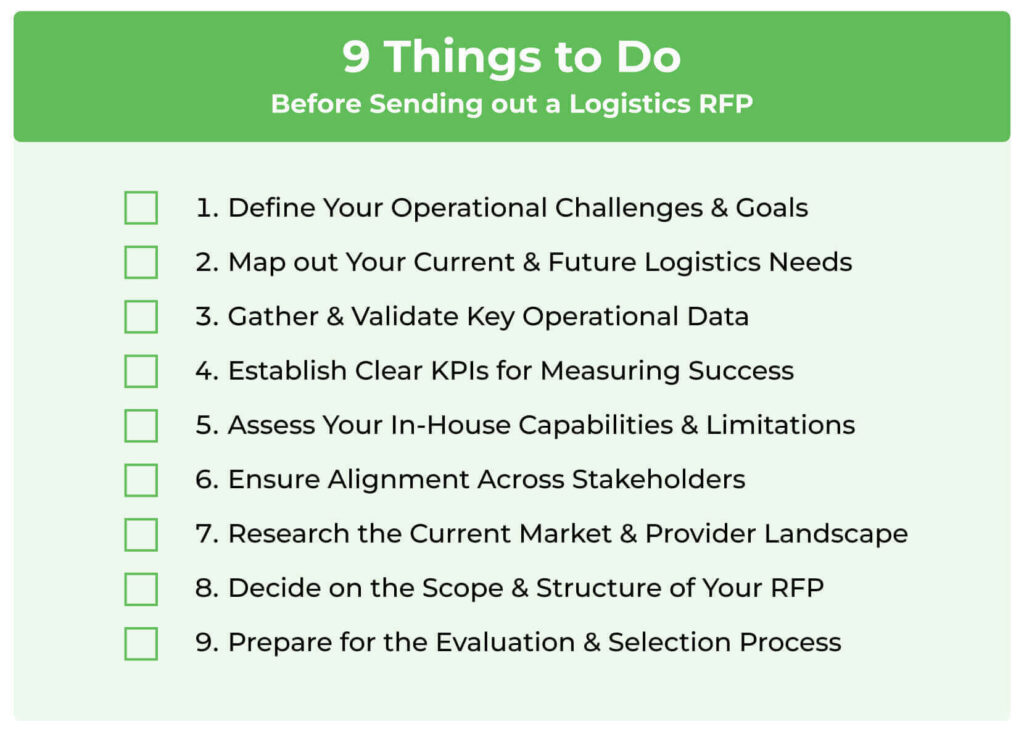

9 Things to Do Before Sending out a Logistics RFP

A well-executed logistics RFP process starts long before you actually send out your RFP to potential providers. To attract the right 3PLs and receive meaningful, actionable proposals, you need to lay the groundwork internally.

1. Define Your Operational Challenges & Goals

Before engaging with 3PLs, get crystal clear on why you’re outsourcing or changing providers. Are you struggling with high fulfillment cost, inconsistent service levels, poor inventory visibility or limited scalability? Your RFP should communicate these challenges, as well as what success looks like to you — whether that’s faster shipping times, better order accuracy, lower transportation costs or greater supply chain resilience.

2. Map out Your Current & Future Logistics Needs

A 3PL partnership isn’t just about solving today’s problems, it’s about enabling future growth. Assess your current distribution, fulfillment and/or transportation needs but also consider where your business is heading. Are you planning to expand into new markets or regions? Launching additional sales channels? Preparing for seasonal volume spikes? Make sure your logistics RFP reflects both immediate and long-term requirements.

3. Gather & Validate Key Operational Data

RFP responses will only be as good as the data you provide. Incomplete or inaccurate information will lead to vague, unusable proposals. Before issuing a logistics RFP, collect and validate:

- Order volumes (including monthly and seasonal fluctuations)

- Stock keeping unit (SKU) counts and product dimensions

- Average order size and shipping profiles

- Current transportation lanes and volumes

- Warehouse locations and capacity constraints

- Required service levels (e.g. order accuracy, on-time delivery rates)

4. Establish Clear KPIs for Measuring Success

What metrics will you use to evaluate your 3PL partner’s performance? Whether it’s inventory accuracy, fulfillment speed, carrier performance or cost per order, defining key performance indicators (KPIs) in advance helps set expectations — and ensures providers can commit to measurable results in their proposals.

5. Assess Your In-House Capabilities & Limitations

Outsourcing logistics doesn’t mean handing over all control. Determine what you intend to retain in-house — such as, say, demand planning, customer service or returns management — and where you’ll need external support. Additionally, assess whether your internal teams have the technology and expertise to effectively collaborate with a 3PL. If not, be prepared to invest in training or system integrations.

6. Ensure Alignment Across Stakeholders

A logistics RFP isn’t just a procurement exercise — it impacts multiple departments across your organization, from operations and supply chain management to finance and customer service. Before issuing an RFP, make sure all key stakeholders agree on goals, priorities and decision-making criteria to avoid delays and misalignment later in the process.

7. Research the Current Market & Provider Landscape

The logistics industry is constantly evolving — what made sense five years ago might not be the best fit today. Before initiating the RFP process, take time to familiarize yourself with:

- 3PL market trends, such as automation, sustainability and nearshoring

- Technological advancements, including transportation and warehouse management systems and AI-driven forecasting

- New pricing models and service structures

- Which providers specialize in your industry

Doing the legwork beforehand will help you set realistic expectations and attract the right providers.

8. Decide on the Scope & Structure of Your RFP

Will your RFP be a broad search for a new logistics partner or a targeted bid process amongst pre-vetted providers? Will it include both qualitative (capabilities, experience, culture) and quantitative (pricing, SLAs) requirements? Defining the structure of your logistics RFP now ensures you get the depth of responses you need.

9. Prepare for the Evaluation & Selection Process

Many companies send out RFPs without a plan for how they’ll review responses and select a provider. Before issuing an RFP, determine:

- Who will review proposals, and what criteria they’ll use

- How providers will be scored or compared

- Whether there will be follow-up rounds, site visits or negotiations

- A timeline for final selection and contract execution

Setting these parameters keeps the entire process structured and efficient, avoiding unnecessary delays.

The 8 Steps of the Logistics RFP Process [& What to Do at Each One]

Selecting the right 3PL provider requires more than just sending out an RFP and reviewing proposals. It’s a multi-step process that requires careful planning, collaboration and strategic decision-making. Here’s how to execute a logistics RFP from start to finish.

Step 1: Recognizing the Need for a 3PL

Most sourcing or logistics managers don’t wake up one day and think, “You know what would be fun? Running an RFP.” Instead, they issue an RFP because something isn’t working — maybe their supply chain is straining under growth or their current provider just isn’t cutting it.

If you’re experiencing any of the following, it may be time to consider outsourcing logistics:

- Capacity constraints: You’re running out of warehouse space, struggling to meet peak demand or can’t scale operations efficiently.

- Rising costs: Your logistics spend is creeping higher without a clear return on investment.

- Service failures: Late shipments, lost inventory or inaccurate order fulfillment are becoming common complaints.

- Lack of expertise: You’re navigating complex compliance requirements — hazardous materials, cold chain, international shipping and so on — and need a partner with specialized expertise.

- Technology gaps: You lack visibility into inventory, are struggling with outdated systems or need better integration with your sales channels.

A word of advice: Rushing into an RFP — or skipping it altogether — can lead to costly mistakes, such as:

- Choosing a provider based on price alone (and paying for it later with service failures)

- Overlooking key requirements, forcing you to switch 3PLs within a year

- Partnering with a 3PL that can’t scale as your company grows

The right 3PL isn’t just a vendor; they’re an extension of your business. Taking the time to get this process right ensures you find a partner that aligns with your strategy, budget and goals.

Step 2: Defining Your Logistics & Business Requirements

Before you can find the right 3PL, you need to clearly define what “right” means for your business. Too often, companies issue vague RFPs and end up drowning in proposals that don’t actually meet their needs. While this is better than the alternative — radio silence — it creates a lot of additional work for your company without the payoff. The more specific you are up front, the better responses you’ll get, and the easier it will be to compare providers.

What services do you need? Start by listing out exactly what you expect your 3PL to handle. This may include:

- Warehousing and distribution

- Transportation management

- eCommerce fulfillment

- Specialized logistics

- Value-added services

If you’re unsure what services you’ll need two or three years from now, build in flexibility. A 3PL that meets your current needs but can’t grow with you will only force another RFP down the line. With that in mind, ask yourself:

- Will our order volumes increase significantly within the next 12 to 36 months?

- Are we planning on expanding into new sales channels?

- Do we need multi-node fulfillment to reduce shipping times and costs?

Pro tip: If a 3PL only looks at your current numbers and doesn’t ask about growth projects, that’s a red flag. A qualified provider will help you plan ahead.

Finally, when defining requirements, make sure you’ve secured input from every key stakeholder — not just procurement or supply chain teams. This includes:

- Operations: What efficiencies do they need to improve fulfillment speed and accuracy?

- Finance: What cost structures make sense, and how do they align with your budget?

- IT: What systems and integrations do you require for seamless data flow?

- Customer service: What delivery SLAs will have the greatest impact on customer satisfaction?

Step 3: Building Your Evaluation Criteria

Not all 3PLs are created equal. Some specialize in high-volume fulfillment, others in complex, multi-modal transportation. Some excel at automation, while others rely on manual processes that will slow you down. Without clear evaluation criteria, you risk choosing a provider based on gut feeling — or worse, just the lowest bid.

Your evaluation criteria should focus on five key areas:

1. Operational capabilities & service offerings

- Can they provide all of the services you need (warehousing, transportation, fulfillment, etc.)?

- Do they have experience in your industry?

- Do they offer multi-node fulfillment for fast delivery?

- Can they handle seasonal surges or unexpected volume spikes without service disruptions?

2. Technology & visibility

- What warehouse management system (WMS) and transportation management system (TMS) do they use?

- Can their technology integrate seamlessly with your enterprise resource planning (ERP) system, eCommerce platform and order management system?

- Do they provide real-time inventory visibility and tracking?

- How advanced are their automation capabilities, and do they have compelling efficiency metrics?

3. Compliance & security

- Are they compliant with industry regulations?

- Do they follow strict data security and cybersecurity protocols?

- What measures do they have in place for risk management and disaster recovery?

4. Financial stability & cost structure

- Are they financially stable? (You don’t want a provider that folds mid-contract.)

- How do they structure their pricing (fixed vs. variable costs, accessorial fees, peak surcharges, etc.)?

- Do they provide clear, transparent billing to avoid hidden costs?

- Can they offer volume discounts?

5. Customer support & account management

- Will you have a dedicated customer success manager, or will you be passed around a customer service queue?

- What is their average response time to issues and escalations?

- Do they provide regular performance reporting and continuous improvement plans?

Step 4: Creating a Strong RFP Document

Your logistics RFP is the blueprint for your entire selection process. We’ll cover the different components your document needs to include — plus tips on how to make sure it’s detailed enough to elicit high-quality responses — in our next section.

Step 5: Identifying & Inviting the Right 3PLs

Once you have an airtight logistics RFP, the next step is to make sure it lands in the right hands. Sending your RFP to the wrong 3PLs wastes your time and theirs. Your goal here is to create a shortlist of providers that align with your needs before you start receiving proposals.

There are plenty of logistics providers, but not all of them are built for your business. To filter through the noise:

- Ask colleagues, suppliers or industry groups for recommendations. A solid referral beats a cold Google search.

- Reach out through your professional network to fellow supply chain leaders, since they’ve likely been through this process before.

- Talk to current or past vendors. You never know if your carrier, warehouse provider or software partner has recommendations.

- Check out 3PL marketplaces, directories and groups such as the Council of Supply Chain Management Professionals (CSCMP) and the International Warehouse Logistics Association (IWLA) to identify reputable providers.

- Send out a brief RFI before committing to a full RFP.

To avoid overwhelming yourself, create a shortlist of five to eight serious contenders.

Step 6: Sending RFPs & Managing Incoming Bids

You’ve built a strong logistics RFP and carefully selected which 3PLs to send it to. When reaching out to the providers in your shortlist, be mindful to:

- Set clear deadlines and expectations. Running a structured process will help avoid any chaos. When you reach out to prospective providers, provide them with a clear timeline, including a deadline for questions and for proposal submissions. Make sure you allocate sufficient time to thoroughly review proposals, schedule follow-ups and site visits (if needed) and discuss finalists.

- Answer 3PL questions. Serious candidates will have questions for you — this level of engagement can tell you a great deal about their professionalism. You might consider gathering questions from all prospective providers and using them to create a consolidated FAQ document, thereby ensuring fairness and transparency. And beware any 3PL that submits a proposal without asking any questions, as this may indicate a lack of due diligence. Either your RFP was exceptionally clear (which is rare), or they didn’t dig deep enough to understand your needs.

- Align internally before reviewing proposals. Creating a scoring system based on your evaluation criteria, ensuring all decision-makers are on the same page before shortlisting finalists and scheduling follow-up calls or site visits can help prevent bias or misalignment in the selection process.

Step 7: Evaluating & Scoring RFP Responses

By now, you’ve (hopefully) received a stack of logistics RFP responses from potential partners. Some will be thorough, some will be vague and some will look great on paper but fall apart under scrutiny. To cut through the noise and objectively determine which 3PL is the best fit for your business:

- Use a structured scoring system. If a 3PL excels in one area but lags in another, weigh trade-offs carefully. A provider with best-in-class pricing but outdated technology might cost you more in inefficiencies over time.

- Conduct follow-up calls and site visits. Proposals only tell half the story. A 3PL may look great on paper but struggle when you start asking tough questions. When talking to potential partners, ask direct questions probing their capabilities — for example, “Describe a time when a major disruption impacted operations — how did you handle it?” or “Who will be our day-to-day point of contact, and what’s your escalation process for urgent issues?” Wherever possible, schedule an in-person visit to candidates’ facilities to get an up-close look at how they manage operations.

- Verify references and past performance. A good 3PL should provide client references. But don’t just ask for them — actually call them. See why they chose that 3PL over others, how well the 3PL handled unexpected issues, whether they would choose to work with that 3PL in the future and so on. If a 3PL refuses to provide references or gives evasive answers about past clients, proceed with caution.

- Compare pricing in context. Pricing is important, but cheaper isn’t always better. When reviewing cost structures, consider total cost of ownership (will you save money with efficiency, even if base rates are higher?), hidden fees (are their pricing models transparent, or full of “gotcha” costs?) and scalability (will costs spike as you grow, or do they offer volume-based pricing?). If a 3PL is significantly cheaper than others, dig deeper to see whether they may be cutting corners on service, technology or staffing.

Step 8: Finalizing Your 3PL Selection

You’re nearing the end of the road, and it’s time to make your choice. By this point, you should have one to two clear frontrunners; be sure to resolve any lingering questions or concerns before you choose a provider and enter into final negotiations.

Once you’ve selected a 3PL, review your contract to make sure it includes:

- Defined SLAs and performance metrics

- Exit strategy and termination clauses

- A clear pricing breakdown

- Data ownership and technology access

- Liability terms and risk allocation

You’ll also want to work with your new 3PL partner to develop a transition plan that ensures a smooth handoff and minimizes disruption. This transition plan should include a timeline with key milestones, a tech integration plan, your account management structure and a staff training and communication plan.

12 Items Every Logistics RFP Should Include

To create a comprehensive logistics RFP that 3PLs will actually want to respond to, be sure to include the following elements:

1. Non-disclosure agreement (NDA): Before getting into details, lock confidentiality. An NDA protects both your business and the 3PL, ensuring sensitive supply chain data, pricing structures and operational insights stay secure. A solid NDA can build trust right out of the gate — and trust is the foundation of any successful logistics partnership.

2. Introduction: This is your chance to introduce your company and make your RFP stand out. A strong introduction should answer key questions:

- Who are you? (Company background)

- What do you do? (Products, services, customers)

- What’s your delivery philosophy? (Speed, accuracy, flexibility, sustainability?)

- Why are you issuing this RFP? (Business goals, pain points, expected outcomes)

Be clear, and be compelling. 3PLs receive a large volume of RFPs every day — make yours one they want to respond to.

3. Schedule: Lay out the timeline for your RFP process, including key dates:

- Intent to participate deadline

- Follow-up question submission date

- Final proposal due date

- Award notification date

Also, clarify who’s responsible for each milestone and provide a contact for any timeline-related questions. Clarity up front avoids confusion later.

4. Term of contract: How long will this partnership last? Contracts can range from a few months (for short-term projects) to multi-year commitments (for long-term fulfillment or distribution needs). Setting expectations early helps 3PLs propose the right solutions for your timeframe.

5. Pricing: Pricing models vary widely across 3PLs, from cost-plus to transactional, fixed variable and incentive-based structures. To accurately compare proposals, you need to understand:

- Your cost structure (What’s your landed cost threshold? How do logistics costs impact margins?)

- Cash flow requirements (How does pricing affect working capital?)

- Capital investment considerations (Will you need to invest in new technology, warehouse racking or material handling equipment?)

6. Response requirements: If you want detailed, useful responses, be specific about what you need. Outline exactly what the proposal should include, such as:

- Logistics concept

- Variable handling costs (per shipment)

- Facility locations

- Startup costs

- Storage requirements

- 3PL responsibilities (equipment, staffing, fees, etc.)

7. Evaluation criteria: Define how you’ll assess responses before they start rolling in. Whether you use a formal scoring system or a more flexible approach, outline:

- What matters most (Pricing, technology, service capabilities, industry experience?)

- Who’s evaluating the proposals (Decision-making team, procurement, operations, finance?)

- How many selection stages (Initial review, shortlist, interviews?)

A clear evaluation framework ensures equitable comparisons based on uniform criteria, so you can focus on what really drives success.

8. Current business operations: 3PLs can’t offer custom-fit solutions if they don’t understand your business. The more context you provide, the better proposals will be, so include key details such as:

- Product portfolios (SKUs, volume, packaging)

- Sourcing locations

- Current order fulfillment process

- Seasonality and peak volume trends

9. Service requirements: This is where you’ll set expectations, avoiding surprises down the line. Define service levels for:

- Order fulfilment (Accuracy, speed, scalability)

- Inventory management (Stock levels, turnover, visibility)

- Transportation (Inbound, outbound, carrier relationships)

- Returns processing (Handling, speed, customer experience)Value-added services (Customization, kitting, labeling)

- Technology integration (WMS, TMS, real-time tracking)

10. Response format: A structured response format makes comparing proposals faster and easier. Request specific sections, including:

- Company overview

- Network locations and capabilities

- Operating hours and staffing structure

- Technology stack

- Proposed solution and implementation plan

- Metrics and KPIs

- Pricing model

- Case studies and references

- Risk management and contingency planning

11. Culture: You aren’t just hiring a vendor — you’re choosing a strategic partner. Cultural alignment plays a huge role in the long-term success of your 3PL partnership, so consider outlining what matters to you, such as:

- Core values

- Recruitment and retention strategy

- Commitment to safety

- Leadership development

Though culture fit may not seem urgent, misalignment here can derail even the best operational match.

12, Questions: Wrap up your RFP with any remaining questions that didn’t fit into previous sections. Be sure to ask anything that could impact your final decision, such as how 3PLs handle volume surges, how they approach continuous improvement and how they measure customer success.

Need help structuring your logistics RFP?

8 Tips for Evaluating RFP Responses [& Choosing the Right Provider]

Once you start receiving proposals, the real work begins. Evaluating prospective 3PL providers is about more than just ticking boxes — you need to find a 3PL that fits your operations, scales with your growth and aligns with your strategic goals. Here’s how:

1. Start with non-negotiables. Make sure each 3PL meets your baseline requirements regarding infrastructure, service levels, locations, transportation network and technology. If a provider can’t meet these foundational needs, move on.

2. Look beyond the price tag. Cost matters, but the cheapest option isn’t always the best deal. A low upfront cost can lead to higher expenses down the road if the provider lacks efficiency, scalability or operational excellence. Instead, focus on total cost of ownership.

3. Assess operational expertise and flexibility. Your business isn’t static; your 3PL shouldn’t be, either. A strong logistics partner is one that adapts as your needs change, from handling seasonal spikes without disruption to scaling warehousing space and labor as your business grows.

4. Carefully review performance metrics. Any provider can talk a big game — demand the data to back it up. Review key KPIs, such as order accuracy rate, on-time fulfillment percentage, inventory shrinkage rate and client retention rate to ensure you’re making the right choice. A high-performing 3PL should be more than willing to share their historical data and client success stories.

5. Evaluate cultural and strategic fit. Your 3PL provider should be an extension of your supply chain team. If there’s a cultural mismatch, the partnership will struggle. With that in mind, consider:

- Are they proactive and solution-oriented, or are they just order-takers?

- How do they handle communication and issue resolution?

- Do they share your values around customer experience, innovation or sustainability?

6. Test their technology. Real-time inventory visibility and seamless integration between your sales channels and your 3PL’s WMS is more than a nice-to-have — they’re a need-to-have. Before signing with a 3PL, make sure they’re leveraging the latest-and-greatest technology and able to integrate with your sales platform, regardless of which software provider you use. Not only will this improve decision-making and reduce errors — it’ll save you money in the long run.

7. Check their contingency plans. Disruptions happen. What matters is how your 3PL plans for and responds to them. Ask about their disaster recovery and business continuity plans, strategies for labor shortages and supply chain disruptions and backup fulfillment options in case of network failures to ensure all your bases are covered in the event of disruption.

8. Trust, but verify. When prospective partners tell you how great their company or logistics services are, don’t just take their word for it — talk to their clients. Request references, case studies and site visits. The best 3PLs won’t hesitate to prove their value.

Preparing to issue an RFP in your search for the perfect 3PL partner? Add Legacy Supply Chain to your list. With over 40 years of logistics industry experience, we have the operational know-how, best-in-class technology and supply chain infrastructure to help you stay more connected to your customers by giving you control of your supply chain, improving your cost-to-serve and enabling growth and scalability. To learn more about Legacy, contact us today.

Frequently Asked Questions

What is an RFP in logistics?

A request for proposal (RFP) in logistics is a formal document companies use to solicit bids from third-party logistics (3PL) providers. It outlines service requirements, operational needs, pricing expectations, selection criteria and more to ensure prospective partners submit detailed proposals that align with the company’s supply chain strategy. A well-structured RFP process helps businesses make informed, data-driven decisions when selecting a logistics partner.

Who sends the RFP?

Businesses that require warehousing, fulfillment, distribution or transportation services typically issue RFPs. This includes retailers, eCommerce brands, manufacturers and wholesalers seeking logistics support. The process is often led by procurement teams, supply chain executives or operational leaders responsible for selecting a provider that aligns with the company’s goals.

Why is sending out an RFP important for finding a 3PL provider?

Issuing an RFP ensures that companies evaluate 3PL providers based on objective criteria rather than relying on sales pitches or surface-level discussions. A well-structured RFP process enables businesses to compare service capabilities, scalability, pricing models, cultural alignment and more, making it easier to identify a provider that meets both short-term needs and long-term growth objectives.

What is the RFP process in logistics?

The typical RFP process is as follows:

- Recognize the need for a 3PL.

- Define your logistics and business requirements.

- Build your evaluation criteria.

- Create a strong RFP document.

- Send out RFPs and manage incoming bids.

- Evaluate and score RFP responses.

- Finalize your 3PL selection.

What sections should a logistics RFP include?

A complete logistics RFP should include the following:

- A non-disclosure agreement

- An introduction to your company

- An RFP process timeline

- Terms of contract

- Pricing and budget

- Response requirements

- Evaluation criteria

- Current business operations

- Service requirements

- Desired response format

- Cultural requirements

- Questions

What are three questions an RFP should include?

Every logistics 3PL should include an entire list of questions that go beyond the basics to assess a provider’s real-world capabilities. At minimum, though, it should include these essential questions:

- How do you handle seasonal volume spikes, and what strategies do you use to maintain service levels during peak periods?

- Can you provide examples of how you have helped clients improve supply chain efficiency and reduce costs?

- What technology platforms do you use, and how do they integrate with our existing systems for real-time visibility?

Download this free template and get everything you need to create the perfect RFP and to find the 3PL partner that’s the right fit for your business.

-

6 Cornerstones to a Successful 3PL-Customer Relationship

Hiring a third-party logistics (3PL) provider is a strategic approach for businesses to increase their capacity without expanding their...

+ Read more -

Canadian Rail Strike? – What We Know So Far

On May 1st, CN (Canadian National Railway) and CPKC (Canadian Pacific Kansas City) rail workers voted overwhelmingly to authorize a strike...

+ Read more -

2024 Q1 Freight Landscape: Trends, Challenges, and Predictions

As the first quarter of 2024 comes to an end, here are some observations over the past few months as well as predictions about the trucking...

+ Read more