Retail: Fortune 500 Retailer

Customer Success Story: Fortune 500 Retailer

Business Issue: Shipment Delivery Visibility

Overview

The following is a story of one of the largest retailers in the US leveraging a dedicated transportation solution to drive value into their supply chain. This member-based wholesale chain has over 600 club locations across the country, serving nearly 50 million members annually. This retail giant drives cost and service efficiencies in the supply chain through a complex network of outsourced 3PL partners – allowing them to offer quality products at low cost to their customers. They are committed to sustainability and supporting small businesses, and have consistently focused on expanding their offerings to online and in-person customers alike.

LEGACY has a longstanding relationship with the company behind this major retail chain, operating multiple dedicated distribution facilities in the Midwest. In 2009, after some struggles with an incumbent provider, the company approached LEGACY to take over distribution facility operations in the Southern California market. LEGACY was able to leverage its existing supply chain footprint in Southern California to provide a solution for the retail conglomerate.

The warehousing & distribution partnership established a track record of success, and in August 2010, LEGACY bid on and won contracts for multiple dedicated transportation lanes in the Southern California market. Some clubs in the region had been experiencing service challenges with existing providers, and LEGACY was able turn those experiences around through increased communication, leadership and a better brand of service.

Building off of the successes realized from the initial set of lanes, the same retailer approached LEGACY in August 2012 to become the dedicated service provider for the entire Southern California market. LEGACY proposed an asset-based, dedicated service model to meet the company’s needs in the region. As a result, LEGACY was named the dedicated service provider for all 24 locations in Southern California, as well as in Las Vegas (through an interline carrier). Within the first year, LEGACY executed successfully on every recommendation, and improved performance so significantly that they were awarded the company’s “Carrier of the Year.”

Here’s how:

Specific Challenges:

Service & Communication: The retailer was experiencing service issues with the previous provider in the region. Communication and shipment delivery visibility was not consistent, and continuous improvement initiatives were not being driven proactively.

Shipment Order: The pickup and delivery process was not optimized. This resulted in the accruing of full truckload shipments for delivery and sometimes in full shipments having to be returned to the distribution center. The company often incurred higher costs due to the carrier not properly managing deadhead mileage, as well as add-on charges for empty deliveries and redeliveries. There were also increased internal labor costs as a result of the provider’s inefficient process.

Carbon Footprint: The frequency of undeliverable shipments going back to the facility was wasting time, money, and fuel. With the company’s commitment to environmental sustainability, the carbon footprint issue was cause for concern.

Solutions and Results:

Service & Communication: LEGACY promised from the start to over-communicate, and they followed through, keeping all managers and clubs updated with proactive daily contact. Visibility to shipment status was communicated personally, and also electronically, through EDI connectivity and online tracking tools.

Shipment Order: As reinforcement to the strong partnership, the retailer allowed LEGACY to maintain full responsibility for the shipment order process, take over the delivery and pickup scheduling, and establish protocols to better manage inbound and outbound trailer activity. This process improvement saved both companies significant costs by reducing deadhead mileage and redelivery fees, allowed for labor to be reallocated to other more essential functions, and also drove efficiency by requiring same day shipment processing.

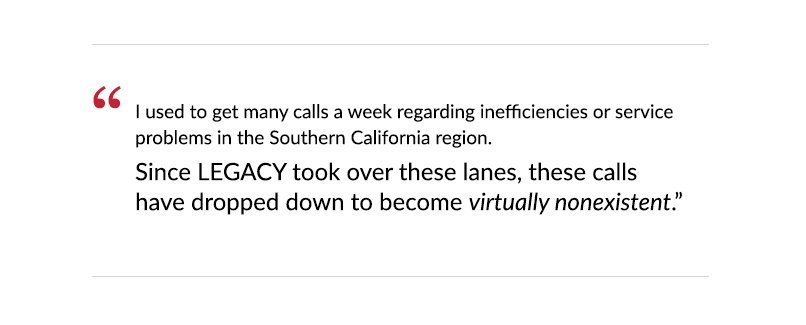

The company’s senior director of Logistics noted the change in overall service:

Carbon Footprint: The company is happy to have reduced their carbon footprint significantly, by taking excess shipments off the road, having a much more efficient pickup and delivery process, and also by utilizing a SmartWay certified transportation provider. This contributes to their company-wide commitment towards a greener environment, and also results in cost savings.

Company KPIs:

-On-Time performance of 98.9%

-EDI (Electronic Data Interchange) performance (transmissions) of 96.8%

Conclusion

What makes this case so successful is the strategic partnership that has developed between this giant retail corporation and LEGACY Supply Chain Services. Both parties communicate regarding challenges, and transparency exists as solutions are executed to meet promised deliverables. LEGACY engages regularly with the company’s regional leadership to develop goals, and a collaborative approach between the two partners ensures both sides are actively involved in continuous improvement. The team dedicated to this retail client is made up of over 30 people, including Wayne Nelson, VP of Transportation, Frank Rodriguez, Sr. Manager of Transportation, and an entire team of customer service agents and dedicated drivers. LEGACY prides itself on professional and safety-conscious drivers, all of whom have developed good relationships with the management at the clubs.

Wayne Nelson attributes the success of this partnership, and the resulting Carrier of the Year award to clear communication, and collaboratively building goals and action plans.

Due to the success of these projects, the Retail Company and LEGACY have saved considerable transportation dollars, and continue to work toward new solutions to further streamline the retailer’s ever expanding supply chain network.

Our warehousing, pool point distribution and dedicated transportation solutions for retailers have been recognized as among the best, by some of North Americas best retailers:

- Walmart Stores, Inc.: Sam’s Club Carrier of the Year

- PVH Performance Excellence Awards

- Sam’s Club 3PL Partner of the Year

-

Legacy Achieves Platinum Status for Delivery Excellence From Amazon

When it comes to supply chain performance, the margin for error is razor thin. Customers expect orders to arrive quickly, accurately, and...

+ Read more -

IPS Corporation selects Legacy as 3PL Partner to drive Supply Chain Transformation

FRANKLIN, IN | September 10th, 2025 – Legacy SCS announced that it has been selected by IPS Corporation, a global leader in Water...

+ Read more -

How GForce Transformed Its Supply Chain Into a Powerful Growth Engine

When GForce Arms launched in 2020, the mission was simple but ambitious: deliver affordable, reliable firearms with the speed and...

+ Read more