Life Sciences Technology Company

Customer Success Story: Life Sciences Technology Company

Business Issue: Warehouse Inefficiency, Waste in Kitting Processes

Company Overview

This case study outlines LEGACY’s work with a global leader in life sciences, diagnostics and applied chemicals, supplying bio-analytical instrumentation and installation services to medical and forensics institutions all over the world. They employ over 10,000 people and bring in nearly $4 billion in revenue each year.

The industries they serve include chemical and energy, pharma and biotech, academia and government, food industry, diagnostic and clinical, and environment and forensics. Growth drivers for the company are issues of increasing global relevance, such as food and water quality, rising energy demands, healthy and aging population, and emerging economies.

The Challenge:

Due to supply chain and warehouse inefficiencies, the client was not meeting the rising demand for field installation kits. This was delaying revenue recognition, and resulting in lost sales.

Statistics:

- Cycle time of 13 hours from dispatch to build

- 6 miles of non-value added travel per day in kitting

- Less than 50% fill rate on customer orders

- Top kits always in red status (critical to build)

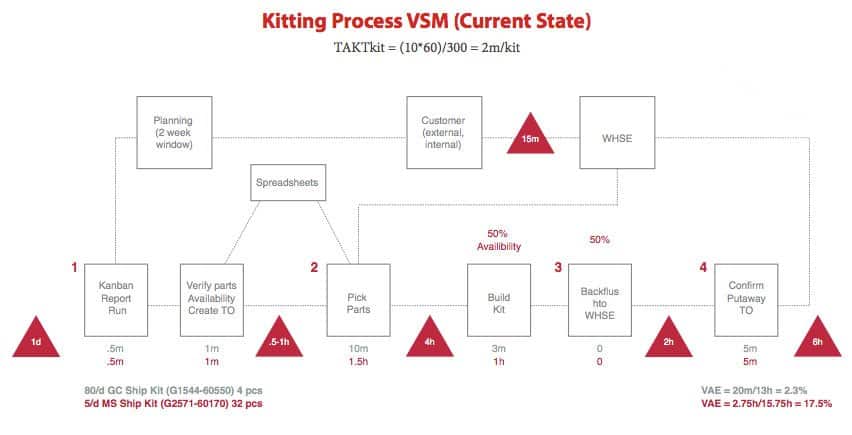

Their setup required 300 feet of walking per kit ordered—a total of six miles per day. Value Stream Mapping (VSM) showed a 13-hour cycle time for the most frequently built kit, rendering them unable to keep up with demand.

The Solution:

LEGACY conducted a 3-day Lean Action Workout, involving corporate, regional, operational, associate and partner representation. This three-day session included group meetings, breakout brainstorming sessions, analysis and recommendations.

They successfully:

- Evaluated the current state using Value Stream Map and waste identification exercises—targeted 50% reduction in cycle time

- Designed work stations and handling equipment to bring most used materials directly to the point of use

- Set up new storage type in SAP, sequenced within current pick/store logic, to drive efficiency

- Shrank work batch sizes by increasing the frequency of SAP-driven Kanban reporting by 200%

The Results:

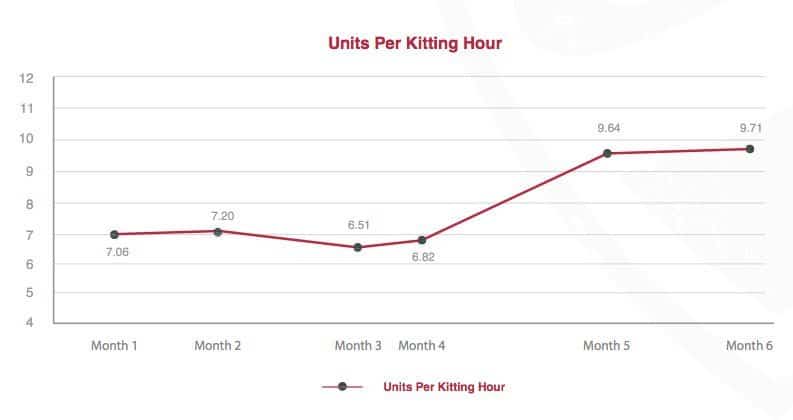

As a result of this Lean Action Workout, efficiency was drastically improved, with:

- 25% reduction in resources used to staff kitting functions, used to support consumable product line

- 55% increase in kits built by team

- 100% fill rate on service kits

- Reduced safety stock levels due to increased production capacity

- Fast reaction to manufacturing/engineering alerts or component changes within kits

The client was able to achieve $72,000 in annual savings as a result of these new efficiencies. As an additional long-term benefit, LEGACY was able to build a culture of continuous improvement by engaging associates, and developing Lean Change Agents to lead projects into the future.

“Through Lean workout projects and process re-engineering, we have driven out excess waste resulting in serious cost savings.”

-LEGACY Lean and Quality Team

-

Legacy Achieves Platinum Status for Delivery Excellence From Amazon

When it comes to supply chain performance, the margin for error is razor thin. Customers expect orders to arrive quickly, accurately, and...

+ Read more -

IPS Corporation selects Legacy as 3PL Partner to drive Supply Chain Transformation

FRANKLIN, IN | September 10th, 2025 – Legacy SCS announced that it has been selected by IPS Corporation, a global leader in Water...

+ Read more -

How GForce Transformed Its Supply Chain Into a Powerful Growth Engine

When GForce Arms launched in 2020, the mission was simple but ambitious: deliver affordable, reliable firearms with the speed and...

+ Read more