Fortune 100 Energy Infrastructure Provider

Customer Success Story: Fortune 100 Energy Infrastructure Provider

Business Issue: Underperforming Distribution Center

Company Overview

This case study outlines LEGACY’s work with a Fortune 100 energy infrastructure provider. This company has global teams designing technology solutions for the transmission, distribution, management, conversion and optimization of electrical power across multiple energy-intensive industries. They bring in over a billion dollars in revenue in over 20+ countries each year.

The Challenge:

Issues with safety, quality and efficiency within pick and consolidation processes.

Specific Challenges:

- Significant safety issues within the facility due to layout, flow of work and PIT travel paths

- Expanding consolidation footprint to handle batch and queue pick work

- Excessive time spent matching product within orders due to significant travel waste

- Unbalanced work levels between pick and consolidation processes

The Solution:

LEGACY conducted Kaizen Blitz as part of a Lean Action Workout, which was two weeks of intense focus on safety, quality, delivery, and cost for pick and consolidation processes corporate, regional, operational, associate and partner representation.

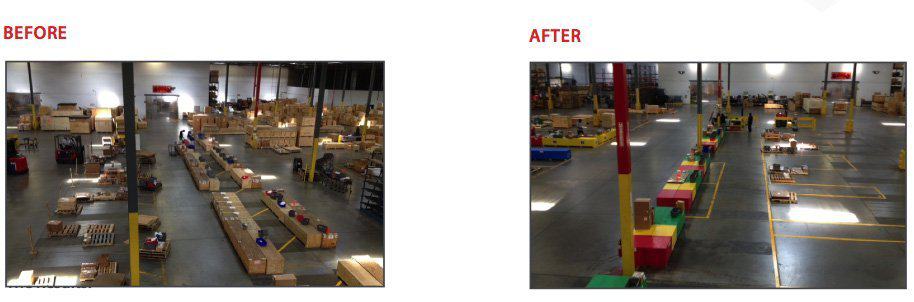

- Surfaced and eliminated traffic and back safety issues with workstation redesign, re-layout and visual management and 5S techniques

- Error-proofed overflow locations to remove risk of lost material

- Improved prioritization of critical work through redesign of dispatch work

- Improved efficiency by reducing travel waste and installing visual levers for correctly flexing resources

- Improved space utilization by creating a crisis – removing 70% of existing staging area

- Developed and implemented continued learning program to ensure adoption of programs- including clear SOP documentation, individual scorecard tracking and performance management to designated productivity, safety and efficiency KPIs

The Results:

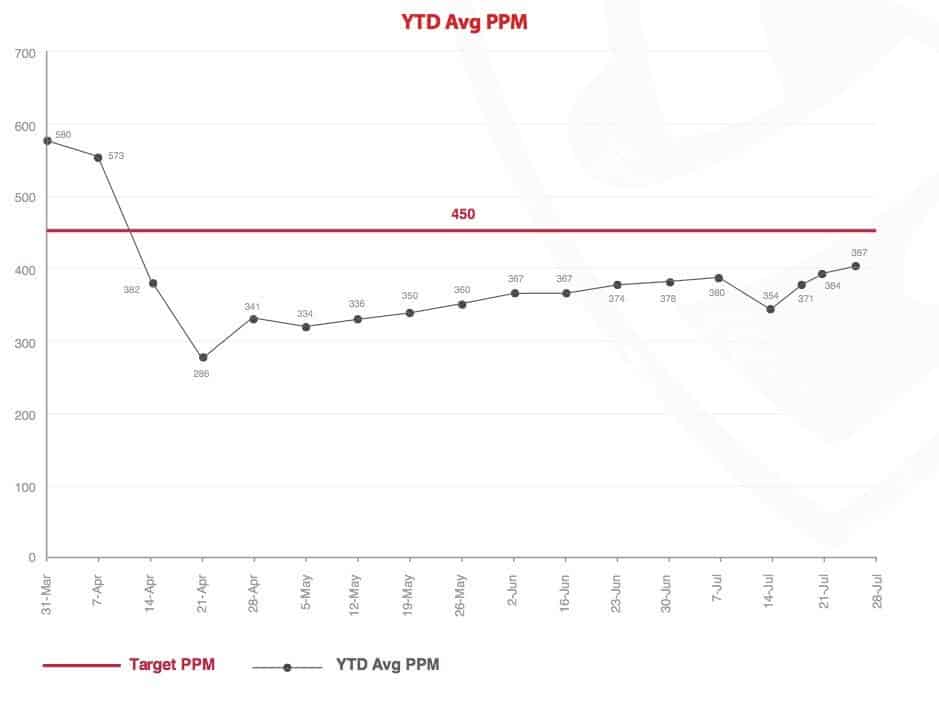

As a result of this Kaizen Blitz, efficiency was drastically improved.

- Zero reported OSHA recordable incidents since Kaizen Blitz

- Reduced PPM below target of 450

- Sustained Rate of 363.73 through 16 weeks post-Kaizen Blitz

- Established and met target of 1300 lines processed per day

- Efficiency gains resulting in savings of $83,654 per annum for the operation

- Reclaimed 5,292 square feet of space in the consolidation processing area

“The LEGACY team conducted Kaizen Blitz as part of a Lean Action Workout and we were proud to see efficiency gains in productivity and safety resulting in significant annual savings.”

-LEGACY Lean and Quality Team

-

Legacy Achieves Platinum Status for Delivery Excellence From Amazon

When it comes to supply chain performance, the margin for error is razor thin. Customers expect orders to arrive quickly, accurately, and...

+ Read more -

IPS Corporation selects Legacy as 3PL Partner to drive Supply Chain Transformation

FRANKLIN, IN | September 10th, 2025 – Legacy SCS announced that it has been selected by IPS Corporation, a global leader in Water...

+ Read more -

How GForce Transformed Its Supply Chain Into a Powerful Growth Engine

When GForce Arms launched in 2020, the mission was simple but ambitious: deliver affordable, reliable firearms with the speed and...

+ Read more